Investment in tech helps Britplas slicken sales process

Last year Britplas invested in a 3d printer, purchased to reduce costs and time lines associated with developing new parts or new design ideas. Prototypes can now be turned around in hours rather than weeks at a greatly reduced cost, helping address sometimes troublesome design issues and so ensuring the right solution is offered.

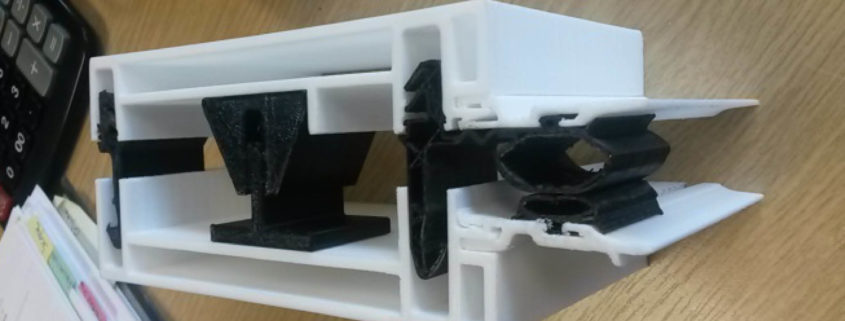

Through printing and sending cross sections of bespoke curtain walling solutions, the sales team was able to visually demonstrate new ideas and designs to both contractors and architects, achieving the best possible result for all. This method was used to solve a number of small but critical design issues on a large project which Britplas successfully tendered for this summer.

The printer works by digitally slicing up a CAD model into a series of layers, each layer is then fed to a heated extruder at 230 degrees, liquefying a plastic polymer before rapidly solidifying to form the desired shape.

Ben Woodward, Britplas Pre-Installations Manager commented ‘We are always looking to help clients and their design teams when looking at unusual or challenging façade design issues and the new printer has definitely made a significant difference in testing ideas and confirming via practical demonstration that certain concepts are viable’.